WHAT WE DO

Novatec creates forming machines with passion and competence, combining the respect of tradition to the vision of the future, to offer customers the best quality worldwide, efficiency, reliability and ensure the required productivity while maintaineng the value over time of the product systems.

The entire production cycle of forming systems, from design and production to installation and testing, is carried out within our factories and by our specialized technicians.

A widespread sales network allows Novatec to constantly follow its customers ensuring a quick repsonse to every request. The wide range of systems produced by Novatec, their versatility and their reliability, allow customers to meet the needs of food packaging ensuring quality, efficiency, and development of new applications.

R&D

Using innovative 3D programming software, our design department realizes the projects of machines, accessories and moulds.

The dept is equipped, also, with a new die-cutting plotter to prepare testing blanks for the new moulds to supply the executive drawing at the customer.

PRODUCTION

Our mechanical workshops, constantly updated with the best CNC production machines, allow us to realize all the mechanical components (from the largest structures to the smallest details).

Some milling machines equipped with special tools are dedicated to the creation of mould forming profiles in order to ensure surfaces with a high degree of finish.

TEST AREA/DEMO

In the assembly department there is a permanent space dedicated to the testing of moulds for our customers.

In this area there is an exhibition area of the most advanced blank fed machines; it is also available, a demo machine for testing and demonstrating our technology and for testing new paper materials to develop new applications/packaging solutions.

Our technicians illustrate our operating procedure and carry out production tests directly with the cardboard blanks supplied by the Customer.

AFTER-SALES SUPPORT

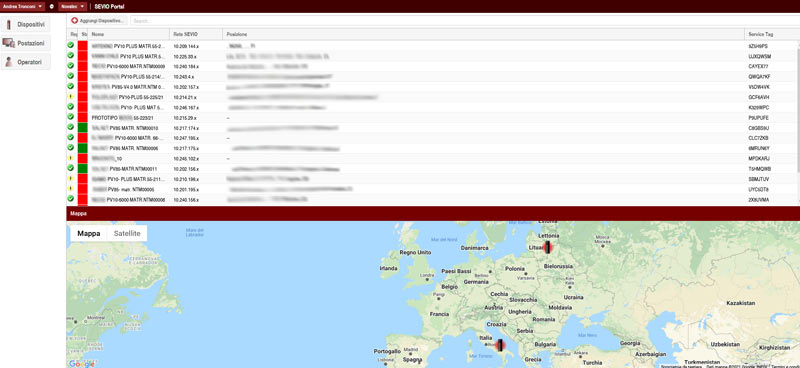

A pool of specialized technicians is always available to respond to any technical needs of customers: from detailed information about our systems to the solution of any problems.

Through the Internet, our technicians can connect remotely to our lates generation machines to verify the machine status and operating parameters as well as intervene for changes and software updates.

A warehouse stocked with all spare parts is available to support any technical problems in a very short time, even if the affected machine has been in production for a long time.

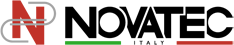

ASSEMBLY

In our assembly departments (one dedicated to blank fed machines and the second dedicated to roll fed machines) the construction of standard machines are flanked by ad hoc systems, mado to meet specific customer needs.

REVISIONS

Our technicians are available to carry out revisions/updates on our customers' machines both in our plants and directly in the production departments of our customers.

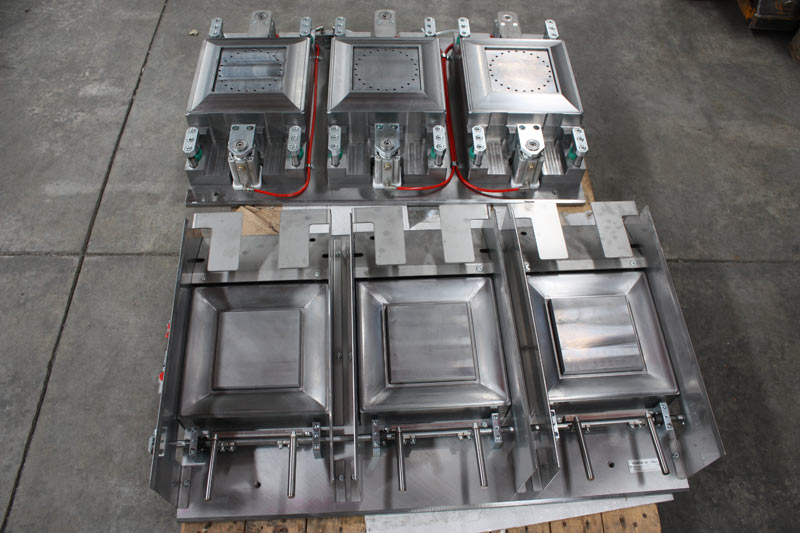

FORMING MOULDS

The moulds are an integral part of our forming systems and, like the machines, are built internally in our headquarters. The moulds are designed with 3D software according to customer requirements. All the projects, drawings, processing programs are stored in our servers to wnsure the reproducibility of the mould even after many years.

The moulds are produced using the best steels and components to ensure their efficiency and durability over the years (our moulds do not have an expiry date; our customers have been using moulds for over 20 years) and tested by our technicians before delivery to the customer.

With the processing parameters that are supplied together with the new moulds, customers only need to install the new moulds on their Novatec machines and start productin.

Novatec can adapt moulds produced for other machines in order to be used on machines of our production.

Novatec also manufactures moulds for other applications accorting to specific customer requirements.